CFM International – Aerospace Industry

CFM56 is a great brand of CFM International company, a 50/50 joint venture between Safran Aircraft Engines and then GE(General Electric Aircraft Engines).

CFM International is a 50% joint venture between GE Aviation (General Electric Aircraft Engines), a division of (GE Aviation) General Electric in the United States(US), and Safran Aircraft Engines (formerly Snecma), a division of Safran in France.

Airbus has a more long-standing of high relationship with CFM International and then its parent companies, GE Aviation and then the Safran Aircraft Engines, and together these partners have established themselves as a provider of high-performance products to meet the needs of airline customers.

Building on the CFM56 engine fleet, Safran Aircraft Engines and GE Aviation (USA) extended the CFM International (CFM) partnership until 2040 in 2008 to develop the more efficient LEAP family of narrow-body aircraft engines.

The history of CFM International

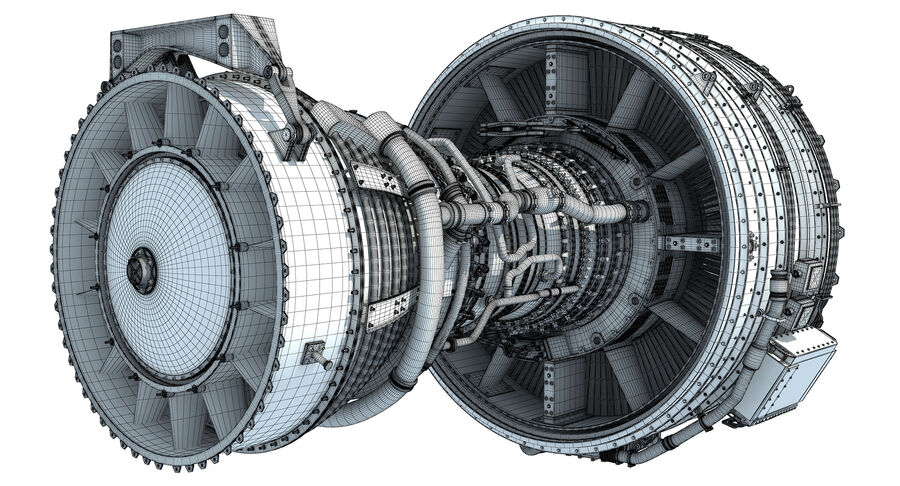

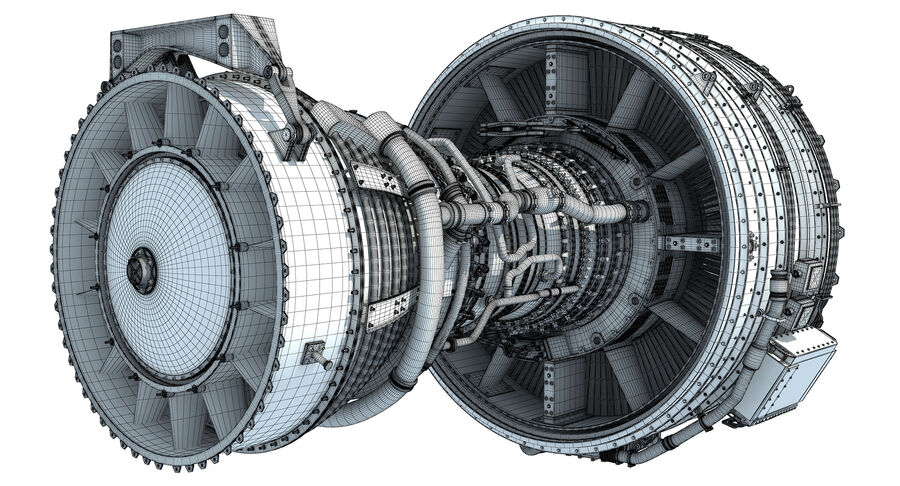

CFM International (the CFM56 and now the LEAP-1 engine) was jointly developed and built by General Electric of the United States and SNECMA of France (now Safran Aircraft Engines), the situation was much more complicated than other types of designs.

CFM International is an international company established by General Electric of the United States and SNECMA of France to produce CFM56-2 high bypass ratio turbofan engines. Over the past decade, the CFM56 engine has become one of the most used in the world, albeit with limited exports.

The LEAP-1B is probably the most popular single-engine turbofan aircraft engine in the world, regardless of any export restrictions. The CFM56 engine range provides between 18,000 and 34,000 pounds of thrust. CFM engines provide reduced takeoff roll, more power, and improved fuel efficiency.

CFM International boasts the highest productivity in the industry and has consistently produced over 1,000 Snecma engines per year since 2006. Since receiving its first order in 2011, CFM International (CFM) has accumulated more than 18,850 LEAP engines on order, making it the best-selling engine in commercial aviation history.

The CFM International and CFM56 products are named by combining the commercial engine names of the two parent companies, General Electric CF6 and Snecma M56.

The two companies work closely together through their respective companies on the design, development, and production of the CFM56 engine. Meanwhile, GE and Safran extended their CFM partnership for a decade with an agreement that began in 1974 and will run through 2050.

The famous aviation company Airbus has signed a partnership agreement with CFM International, and also it is a 50/50 joint venture between GE and then Safran Aircraft Engines GE to work together on a hydrogen demonstration program starting around the middle of this decade.

Massimo Varriani, head of the European system for the hydrogen program at GE Aviation’s Avio Aero, says the “goal of the project demonstrates the technology,” and then the resulting prototype can then be extended to handle a lot of different engine sizes and also a lot of types for aerospace applications.

RISE – Revolutionary Innovation for Sustainable Engines:

The partners decided to “simplify” the overall architecture compared to previous open-rotor motors, which explains to Delfin Dijou, executive director of the CFM RISE systems engineering program at Safran Aircraft Engines.

CFM International has launched RISE, a new open-rotor engine demonstration program that promises a 20 percent increase in fuel efficiency over today’s narrow-body powertrains.

The Revolutionary Innovation for Sustainable Engines (RISE) program, announced in June 2021, aims to develop technology that can lead to an engine that consumes 20% less fuel and produces 20% less CO2 emissions than the world’s most efficient modern jet engines using conventional engines. fuel.

The program’s goals include a reduction in fuel consumption and carbon emissions of more than 20% compared to the current Leap CFM International engine, which in turn resulted in a 15% reduction in fuel consumption compared to the previous CFM56 engine. Arjan Hegeman, who declined to provide specifications, said the temperature-to-pressure ratio in the high-temperature, high-speed core would exceed that in today’s CFM Leap engines.

In December, The great United Airlines operated the world’s amazing first passenger flight with 100 percent of sustainable aviation fuel(SAF) on one of its CFM LEAP1B engines.

CFM International has begun ground testing of the first all-new LEAP-1B engine, which will be used exclusively on the Boeing 737 MAX and Boeing 737 MAX aircraft, three days ahead of schedule.

Conclusion In a sudden order, Canadian flag carrier Air Canada is supplying 122 LEAP-1B engines to operate 61 next-generation Boeing 737 MAX narrow-body aircraft in West Chester, Ohio.

CFM does this by building extraordinary engines and offering specialized services. At the heart of CFM’s rapid and painstaking success is the ingenuity of its designers, engineers, and product support specialists around the world.